Eco-Friendly Foam Glass Board – Fireproof, Waterproof & High Strength

-

A1 Non-Combustible – Maximum fire safety for buildings and industrial facilities

-

High Compressive Strength – Up to 2.4 MPa, suitable for floors, roofs, and heavy-duty areas

-

Near-Zero Water Absorption – Vapor-tight structure prevents moisture and condensation

-

Extreme Temperature Stability – Performs from -268 °C to 480 °C without degradation

-

Chemical & Aging Resistant – Inorganic, non-corrosive material ensures long service life

This page is intended for contractors, distributors, and project buyers looking for A1 fire rated Foam Glass board for construction and industrial insulation.

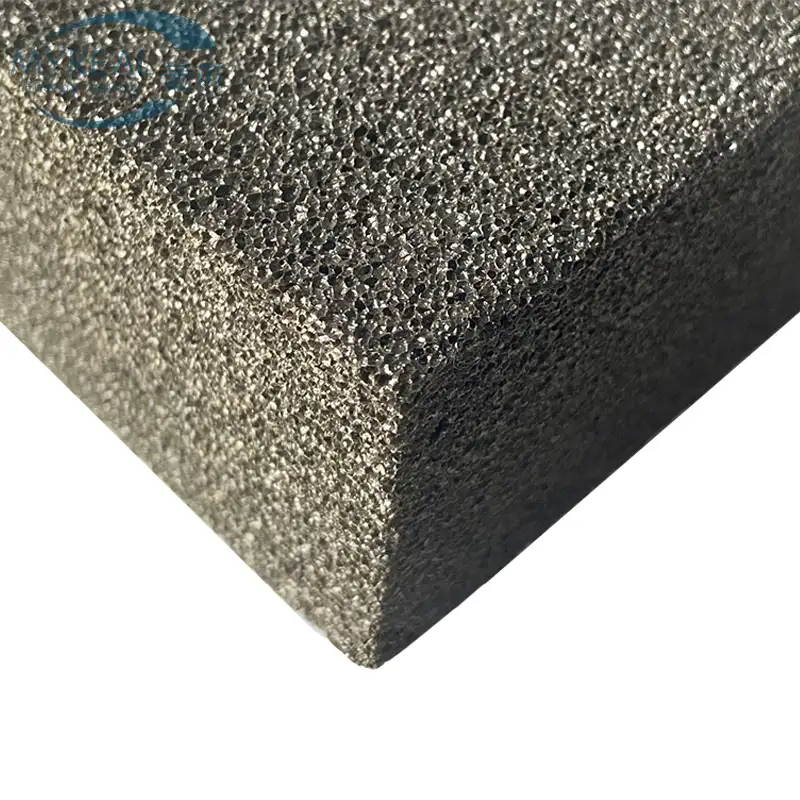

Myreal® Foam Glass Thermal Insulation Board

Myreal® XPS Boards provide high-performance thermal insulation with up to 2.4 MPa compressive strength, excellent water resistance (99.993%), and wide temperature stability from -268 °C to 480 °C.

Available in various density grades and customizable sizes, with aluminum foil or mortar finishes to suit diverse industrial and construction needs.

Manufactured to GB/T and ISO standards, these boards are trusted worldwide for durable, energy-efficient, and moisture-resistant insulation solutions.

Product Features

🔥 Fire Resistance

- A1 Non-Combustible Foam Glass Board – Fire-resistant insulation for safe building use.

- Blocks fire spread in walls, roofs, floors, HVAC systems, and industrial installations.

💧 Water Resistance

- Water vapor permeability ≤ 0.007, effectively preventing moisture penetration.

- Protects building walls, floors, and roofs from dampness and condensation.

⚡ Compressive Strength

- High-density foam glass board with compressive strength 0.5–2.4 MPa (72–348 psi), selectable according to board density.

- Provides excellent support for floors, walls, and industrial installations.

- Ensures long-term durability under heavy loads while maintaining insulation performance.

❄️🌡️ Extreme Temperature Resistance

- Foam glass board withstands temperatures from -268 ~ 480℃ (-450 ~ 896°F).

- Ideal for cryogenic storage, industrial high-temperature equipment, HVAC systems, and building insulation.

- Maintains structural stability and insulation performance under extreme conditions.

🪶 Lightweight & Easy Installation

- Foam glass board is lightweight yet rigid, making it easy to transport, cut, and install.

- Reduces labor and installation time while maintaining high insulation performance.

⚙️ Chemical & Long-Term Stability

- Made from inert, non-corrosive materials, foam glass board resists moisture, chemicals, and aging.

- Ensures stable insulation performance in industrial, commercial, and residential settings.

🧩 Customizable Dimensions, Densities & Facings

- Foam glass boards can be tailored in length, width, thickness, and density to suit your specific project needs.

- Choose from a variety of facing materials to enhance performance and compatibility:

- Mortar-coated facing– boosts bonding with concrete and render layers.

- Lime board facing – perfect for breathable wall construction.

- Cement board facing– designed for high-strength and exterior applications.

- Glass fiber mat facing – improves surface stability and adhesion.

- Aluminum foil facing – acts as an effective moisture and vapor barrier.

Technical Parameters

Standard Foam Glass Panel

| Property | MY-FG/140 | MY-FG/160 | Unit | Test Standard |

|---|---|---|---|---|

| Density | 140±10% | 160±10% | kg/m³ | GB/T 5486 |

| Flexural Strength | ≥0.40 | ≥0.50 | Mpa | JC/T 647 |

| Compressive Strength | 1.00 | 0.70 | Mpa | JC/T 647 |

| Thermal Conductivity (10℃) | 0.050 | 0.056 | W/(m·K) | GB/T 10294 |

| Water Vapor Permeability | ≤0.007 | ng/(Pa·m·s) | GB/T 17146 | |

| Volumetric Water Absorption | ≤0.5 | % | JC/T 647 | |

| Linear Expansion Coefficient | 9×10⁻⁶ | ℃⁻¹ | GB/T 7320 | |

| Service Temperature | -268~480 | ℃ | - | |

High Performance Foam Glass Panel

| Parameters | MY-FG/500 | MY-FG/800 | MY-FG/1000 | MY-FG/1200 | MY-FG/1400 | MY-FG/1600 | MY-FG/2400 | Unit | Test Standard |

|---|---|---|---|---|---|---|---|---|---|

| Density | 115 | 120 | 130 | 140 | 150 | 160 | 220 | kg/m³ | ASTM C303 |

| Flexural Strength | ≥0.283 | ≥0.310 | ≥0.351 | ≥0.386 | ≥0.434 | ≥0.476 | ≥0.627 | Mpa | ASTM C203 |

| Compressive Strength | ≥0.50 | ≥0.80 | ≥1.00 | ≥1.20 | ≥1.40 | ≥1.60 | ≥2.40 | Mpa | ASTM C165 |

| Thermal Conductivity (10℃) | ≤0.040 | ≤0.043 | ≤0.056 | 0.056 | ≤0.047 | ≤0.048 | ≤0.056 | W/(m·K) | ASTM C177 |

| Water Vapor Permeability | ≤0.007 | ng/(Pa·m·s) | ASTM E96 | ||||||

| Volumetric Water Absorption | ≤0.5 | % | ASTM C240 | ||||||

| Linear Expansion Coefficient | 9×10⁻⁶ | K⁻¹ | ASTM E228 | ||||||

| Service Temperature | -268~480 | ℃ | - | ||||||

Calculated as R = Thickness / K, where K = 0.040-0.056 W/(m·K). Typical thickness ranges from 10 mm to 150 mm, giving R-values approximately from 0.18 – 3.75 m²·K/W.

Areas of Applications

Flat Roof & Inverted Roof Systems

Foam Glass Board is commonly used in flat roof and inverted roof insulation systems, where insulation materials are exposed to moisture and mechanical loads.

- A1 non-combustible (fire-safe)

- Zero water absorption

- High compressive strength for foot traffic and rooftop equipment

Typical projects: commercial buildings, data centers, industrial roofs

Basement & Foundation Insulation

For below-grade insulation, Foam Glass Board provides long-term stability under soil pressure and moisture exposure.

- Vapor-tight and moisture-proof

- No capillary water absorption

- Resistant to soil chemicals and aging

Typical projects: underground parking, basements, foundation walls

External Wall & Facade Insulation

Foam Glass Board is suitable for external wall and façade systems where fire safety and durability are mandatory.

- Inorganic and fire-resistant

- Dimensional stability over time

- Compatible with render, cladding, and curtain wall systems

Typical projects: high-rise buildings, public facilities

Industrial Floors & Heavy-Duty Areas

Foam Glass Board is an ideal solution for insulation layers subjected to continuous loads.

- Excellent compressive strength

- No creep under long-term load

- Maintains performance over the building lifecycle

Typical projects: warehouses, factories, logistics centers

Cold Storage & Cryogenic Insulation

Foam Glass Board performs reliably in extreme temperature conditions.

- Stable from cryogenic temperatures to high heat

- No shrinkage or brittleness

- Long service life in cold environments

Typical projects: cold storage facilities, refrigeration plants

Chemical Plants & Process Facilities

Thanks to its inorganic and chemically inert structure, Foam Glass Board is suitable for harsh industrial environments.

- Resistant to acids, solvents, and oils

- Non-corrosive and dimensionally stable

- Fire-safe for high-risk areas

Typical projects:chemical plants, industrial process units

LNG, Oil & Gas Infrastructure

Foam Glass Board is used in projects requiring strict fire safety and moisture control.

- Fire-resistant insulation for critical areas

- Vapor-tight structure prevents condensation

- Suitable for long-term industrial use

Typical projects:LNG terminals, oil & gas facilities

Green Building & Long-Life Construction

Foam Glass Board supports sustainable construction goals through durability and material stability.

- 100% inorganic and recyclable

- Zero VOC emissions

- Long service life (50+ years)

Typical projects:green buildings, passive house developments

Factory & Industrial Environment

Production line pic 1

Production line pic 2

Warehouse pic 1

Warehouse pic 2

Packaging & Delivery

Foam Glass Panels in Polyetser(Plastic) Bags

*Packaging Options:

● Foam glass boards can be packed in cartons or palletized wooden frames upon request.

● Protective packaging is designed to minimize damage during handling, storage, and long-distance transportation.

Loading Scene 1

Loading Scene 2

● A1: Non-combustible material with no flame spread, suitable for use in building envelopes and industrial applications.

Fire performance is tested under laboratory conditions. Final fire safety depends on system design, installation method, and protective layers (e.g., concrete, plaster, or fire-resistant facings).

Standard Sizes & Density

Metric System

| Product | Thickness (mm) | Length (mm) | Width (mm) | Density (kg/m³) |

|---|---|---|---|---|

| Foam Glass Panel | 10-150 | 610/620 | 480/490 | 115-220 |

Imperial / US Customary System

| Product | Thickness (inch) | Length (inch) | Width (inch) | Density (lb/ft³) |

|---|---|---|---|---|

| Foam Glass Panel | 0.39-5.91 | 24/24.41 | 18.9/19.29 | 7.18-13.74 |

*Note: Parameters such as density, thickness, and dimensions can be customized according to project requirements. Higher density improves compressive strength, while lower density is suitable for cost-sensitive insulation applications.